Aiming for modernization and mechanization, the construction industry is undergoing a shift to align with global development. At the same time, the requirements for designing and constructing steel beam-slab structures are becoming more stringent and demand higher quality. The article below will provide a detailed guide to 5 standard steps in designing steel beam-slab structures.

Nội dung

What is a Steel Beam-Slab Structure?

In all construction projects—whether large or small scale, industrial or civil—the steel beam-slab structure plays a vital role in ensuring the overall safety and stability of the building.

With the advancement of modern mechanical engineering, many new materials have emerged. However, steel remains one of the most widely used materials in construction, especially in beam structures, due to its durability and long-term strength.

The beam system of a building typically includes: Main beams, secondary beams, slab beams

These components are interconnected based on one of two common approaches:

-

Overlapping connection: Simple layout, greater height, less stability

-

Face-to-face connection: More complex installation, reduced overall height, improved structural stability

Advantages of Steel Beam-Slab Structures

Steel beam-slab systems are widely used in construction for several key benefits:

-

Greater durability and longevity compared to traditional materials

-

High structural stability and strength

-

Improved safety over time for the entire building

5 Steps to Designing Standard Steel Beam-Slab Structures

To ensure your steel beam-slab system meets technical and safety standards, follow these five essential steps:

Cost Planning

A detailed cost plan allows investors to manage capital efficiently and helps contractors assess the feasibility of taking on a project.

Key components of a cost estimate include:

-

Material unit prices

-

Design and technical drawing costs

-

Material usage norms and labor rates

-

Possible additional expenses

Note: If secondary works are added later, actual costs will likely exceed the initial estimates.

Structural Design of the Steel Beam-Slab System

This is one of the most critical stages, directly impacting the longevity and safety of the entire building.

Must strictly adhere to structural design principles

Ensure precise calculations for load-bearing capacity

Should be carried out by experienced architects (KTS) and structural engineers (KS)

For optimal results, contact a reputable design & construction company to ensure all designs meet industry standards.

Selecting and Preparing Materials

The steel beam-slab system is made from two primary materials:

-

Steel

-

Reinforced concrete (RC)

These materials offer excellent durability and are especially suitable for public and industrial structures where long-term performance is crucial.

Currently, there are many types of construction steel available on the market. To ensure quality, investors should choose steel from reputable brands such as Hòa Phát, Pomina, or Việt Nhật. Businesses should pay attention to the product price, as some units may use assembled steel from China, which is cheaper but does not guarantee quality.

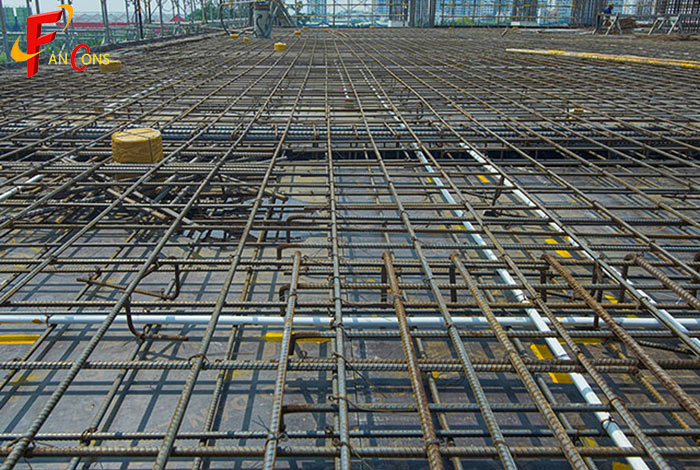

Steel Beam-Slab Layout

Depending on the size of each construction project, the layout of the steel beam-slab structure will vary. Among the options, the beam grid system is a popular method chosen by many contractors and investors. There are three types of beam grids: simple grid, standard grid, and complex grid.

Calculating the Structural Steel of the Beam-Slab

The structural steel of the beam-slab in construction needs to be calculated based on transverse and longitudinal reinforcement.

-

Transverse reinforcement is responsible for shear resistance.

-

Longitudinal reinforcement handles bending moment resistance.

Steel layout by cross-section:

-

Rebar diameter: Choose between 12mm – 25mm; for main beams, 32mm can be used.

Absolutely do not choose rebar with a diameter greater than 1/10 of the beam width.

The diameter between different rebar types must differ by at least 2mm. -

Protective concrete cover: The thickness must be greater than the rebar diameter.

In projects located in areas with saltwater or muddy conditions, the cover thickness should be larger than usual to ensure better protection.

Steel layout by longitudinal direction:

-

In negative moment zones, place the longitudinal reinforcement on top.

In positive moment zones, place it at the bottom. -

Rebars should be concentrated where the moment is highest.

The farther from this area, the fewer rebars are required (they can be cut or bent into new zones). -

Reinforcement bars should be securely fixed at each end.

-

Top and bottom rebars can be arranged either independently or combined.

The combined method is more material-efficient but more complicated and time-consuming to install.

Important Notes When Constructing Steel Beam-Slab Structures

-

Ensure construction quality and worker safety during the design and installation process.

-

Equipment used for fabricating beam-slabs must comply with strict safety standards.

-

Before welding, workers should check all machinery and wear full protective gear to ensure safety.

-

During outdoor construction, if it rains, all work must stop immediately, and proper protection measures should be taken for the beam-slab structure.

-

Avoid storing too much rebar in the active construction area to prevent overloading.

Trusted provider of high-quality steel beam-slab structure production lines

As previously mentioned, steel beam-slab structures play a crucial role in ensuring the stability of the entire construction, especially for projects requiring long-term durability. To meet both quality standards and the necessary production output, steel structure production lines have become a preferred solution for many businesses in the construction industry.

If you’re looking for a reliable supplier of high-quality steel beam-slab structure production lines, Fancons is a leading name you can trust. Proud to be a pioneer in providing modern equipment and high-tech production lines, sourced from top global brands, Fancons is committed to delivering maximum customer satisfaction in every project.

FANCONS CONSTRUCTION GENERAL CONTRACTOR JOINT STOCK COMPANY

Head Office: Nam Cuong Building, La Khe Ward, Ha Noi City

Hotline: 09345 01 333

Email: cgc@fancons.com.vn

Website: https://fancons.com.vn/

Facebook: fancons.com.vn/

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)