Building factories for export processing enterprises has recently become one of the most in-demand services among our clients.Join Fancons as we explore the detailed construction process for factory projects designed specifically for export processing enterprises in the article below.

Nội dung

Characteristics of Export Processing Enterprises (EPEs)

Export Processing Enterprises are businesses specialized in manufacturing goods exclusively for export to foreign markets. These enterprises must be located within export processing zones and have the following characteristics:

Special Policies and Construction Considerations for Export Processing Enterprises

-

Export processing enterprises (EPEs) are exempt from import and export duties on goods exported abroad from the export processing zone, and on goods imported from abroad into the zone.

-

EPEs must be physically separated from surrounding areas by fencing systems, with designated entry and exit gates to ensure customs and government authorities can monitor and control operations effectively.

-

EPEs are allowed to purchase goods from the domestic market for the purposes of manufacturing, processing, recycling, or assembling export goods, or for re-export—excluding goods that are prohibited from export.

-

The following types of goods are permitted to be sold into the domestic market by EPEs:

-

Products manufactured by the EPE that are not on the list of prohibited imports.

-

Products manufactured by the EPE for which there is domestic market demand.

-

Scrap and by-products generated during the production process that are not on the list of prohibited imports or that are allowed to be imported under relevant trade and legal regulations.

-

Construction Considerations for Export Processing Enterprises

Due to these specific characteristics, the construction of factory buildings for EPEs must strictly adhere to relevant industrial park standards and regulations. Several aspects must be carefully considered during the planning and construction phases to ensure full compliance with government and customs requirements.

Factory construction process for export processing enterprises

In addition to the factors mentioned above, EPEs must ensure that the factory construction process follows a complete and standardized sequence of steps as outlined below:

Receiving and Storing Construction Materials

The person in charge must thoroughly inspect all delivered materials and supplies to ensure there are no errors in quantity, type, color, size, etc.

Factory Floor Construction

The factory foundation is crucial in determining the overall stability of the entire facility. Therefore, this stage must be carefully calculated and executed with precision.

Steel Frame Installation

Steel frames are prefabricated at the factory before being transported to the construction site for assembly and erection.

Factory Roof Installation

Once the steel frame is in place, the roofing system will be installed. Currently, galvanized color-coated corrugated iron sheets combined with insulation panels are the preferred materials for their heat and noise resistance.

Construction of Exterior Walls and Interior Partitions

Walls can be built using bricks, corrugated sheets, or other materials depending on the client’s requirements, the type of factory, and the construction budget. The contractor will select the most suitable materials accordingly.

Factory Infrastructure Development

This includes drainage systems, road base treatment, crack prevention, etc., to ensure heavy vehicles can move around the site easily and frequently without damage.

Technical Systems Installation

After completing the infrastructure, the construction team will install essential technical systems such as fire protection, communication systems, and electrical systems.

Finalization and Equipment Installation

This is the final construction phase. Workers will install machinery, paint directional markings on the floor, install gypsum ceilings for office areas, and plant trees and flowers to enhance the factory’s aesthetics.

Cleaning and Handover

After completing all construction phases, the entire factory will be thoroughly cleaned to remove any remaining debris, dust, and paint stains before being handed over to the client for operation.

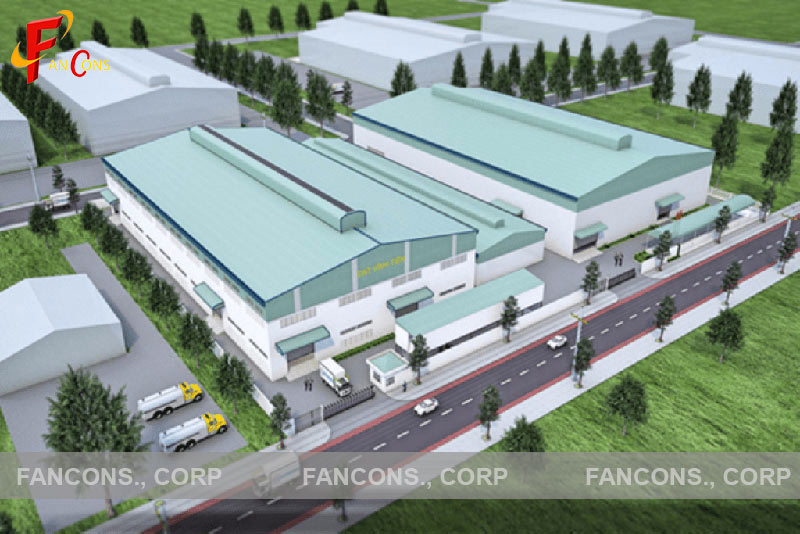

Fancons – Leading Factory Construction Contractor for Export Processing Enterprises

Meeting all of the above requirements is no simple task and can take considerable time, especially for businesses without in-house technical staff. That’s why partnering with a professional construction company is essential.

A qualified contractor will provide optimal solutions tailored to both the enterprise’s needs and regulatory requirements. Most importantly, a structured and professional process helps save valuable time for the business.

With a commitment to always prioritizing quality, Fancons is proud to be one of the leading industrial construction companies in Vietnam. Fancons not only ensures high quality but also delivers aesthetics and timely completion for all construction projects.

With a highly qualified and experienced team, we have successfully implemented numerous projects for both large and small enterprises and corporations.

For detailed consultation on factory construction services for export processing enterprises, customers can contact Fancons via the hotline below:

024.666.43.586 – 0934.593.336

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)