The industrial electrical system must be installed accurately, carefully, and meticulously to avoid risks and potential incidents during operation. To carry out industrial electrical installation, it is essential to have technicians who are well-versed in technical aspects and design drawings. With many years of experience, Fancons and our team of skilled technicians provide customized electrical installation services tailored to the specific requirements of each factory.

Nội dung

Industrial Electrical Installation at Fancons Includes:

-

Industrial factory electrical cabinet systems.

-

Measurement and automatic control systems for boiler parameters in thermal power plants.

-

Automation systems for hydrogen production in thermal power plants.

-

Automation systems for raw water treatment in thermal power plants.

-

Automation systems for demineralized water treatment in thermal power plants.

-

Automation systems for wastewater treatment in thermal power plants.

-

Burner control systems for drying drums at hot mix asphalt mixing stations.

-

Low-voltage soft starters.

-

Medium-voltage soft starters.

-

Automatic control systems for coal supply in thermal power plants.

-

Automatic control systems for ash and slag discharge.

![]() CONTACT NOW: 024.666.43.586 – 0934.593.336

CONTACT NOW: 024.666.43.586 – 0934.593.336

Industrial Electrical Installation for Factories

Factory electrical installation involves the design, drafting, and installation of electrical systems for factories. These systems must align with the specific characteristics of production activities and the operational scale of the enterprise.

The electrical system within a factory is a critically important aspect of construction, as it directly impacts the enterprise’s workflow. Currently, the demand for electricity in industrial zones, factories, and manufacturing plants is significantly high. If you are a business owner, you may need expert consultation and optimal electrical solutions provided by a team of reputable and experienced engineers.

Typically, the process of installing electrical systems in factories and production facilities shares several key components. In this article, we would like to share with you the main components involved in factory electrical installation, along with essential notes to help you gain more knowledge. This will enable you to better supervise key tasks performed by the contractor.

The industrial electrical sector always holds a vital role in supporting both production and daily operations. Basic tasks in industrial electrical installation include:

-

Installing and connecting industrial signal transmission systems.

-

Operating LPC (Logic Programmable Controller) programming devices.

-

Operating microcontroller programming devices.

-

Operating and maintaining industrial electrical equipment, and more.

Process of designing an industrial electrical system for a factory

The process of designing an electrical system that complies with standards and delivers a high-quality electrical layout for a factory typically follows these steps:

1. Power Cable System Design

The power cable system must be accurately and logically calculated.

The design must ensure the technical specifications of the wiring routes and deliver high operational efficiency for the factory.

2. Cable Tray & Ladder Installation Position Design

The layout must not only ensure safety for the electrical cable system and user safety, but also meet high aesthetic standards, being neat and well-organized.

3. Lighting System Design

The lighting system in the factory must be designed and calculated to suit each specific area — such as production zones, living or office spaces, etc.

The objective is to ensure the light intensity meets user needs and adheres to lighting standards.

Factory Electrical System Design Process

-

Provisions for future upgrades and renovations: During factory operations, increased power consumption may cause system overload, leading to the deterioration of equipment beyond the original design capacity. Therefore, it’s crucial to regularly plan for upgrades and improvements to the electrical system.

-

Maintenance and repair plans: Regular inspection and maintenance help prolong equipment life and significantly reduce repair costs. In case of malfunctions, a clear plan and specific maintenance items must be prepared.

-

Plans for relocation of equipment and electrical systems: If machinery and electrical systems must be moved to a new facility, a detailed survey, clear scheduling, and planning are necessary to ensure smooth reoperation and minimize downtime costs.

-

Automation system installation plan: For factories equipped with smart machinery, it is essential to integrate automation solutions, such as PLCs, HMIs, inverters, servos, temperature controllers, etc. This includes HVAC systems for industrial and commercial cold storage. In terms of production lines: electrical wire and cable plants, wood processing, textile dyeing, steel, cement, etc. Maintenance and repair solutions must also be proposed for automated electrical systems in production lines, such as in wood, cable, cement, steel, plastic, concrete mixing, and printing factories.

Industrial Electrical Construction Process

-

Installation of main power cable system: The main power line originates from the substation and connects to the MCCB. From the MCCB, power is distributed to the main switchboard, supplying electricity to the entire system. These cables should ideally be installed underground using metal or PVC conduits.

-

Cable tray and ladder installation: A support system used to fix and secure the main electrical cable routes.

-

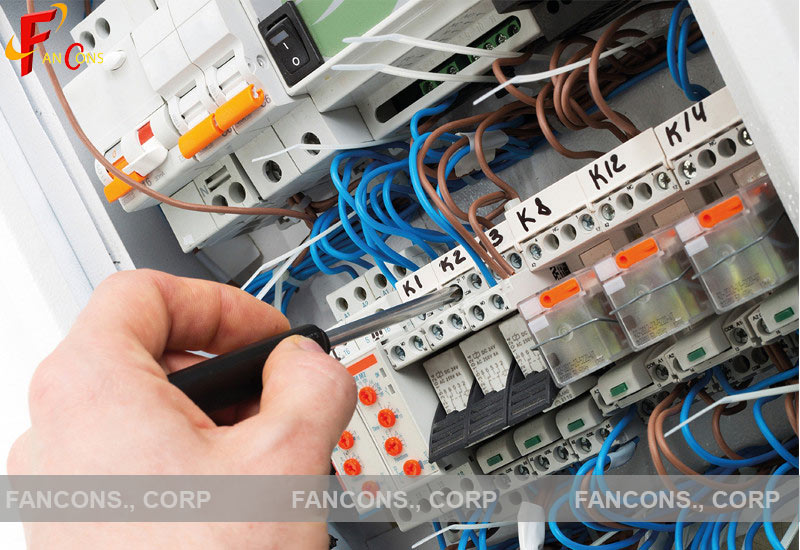

Industrial electrical panel installation: This involves connecting main power lines via circuit breakers and switches. Careful and accurate installation is required to meet both aesthetic and technical standards.

-

Low-voltage system installation: Includes fire alarm systems, lighting, general-use electrical outlets, camera systems, etc.

Turnkey Industrial Electrical Installation Service

-

Precision guaranteed: With an experienced technical team, customers are assured of precision across every phase of construction, ensuring smooth system operations.

-

Budget compatibility: Before starting construction, Fancons provides an estimated quotation to help customers control future costs and limit unexpected expenses.

-

Cost-efficiency: Fancons supplies equipment at competitive prices with verified quality to ensure customers receive reliable industrial electrical components.

Fancons – A Trusted Electrical System Design & Installation Contractor in Hanoi

-

Progress Assurance: To ensure timely execution of subsequent phases such as production operations, clients are encouraged to use professional services. This specialization helps guarantee the project is completed on schedule and as required.

-

Stable Operation: After installation, clients will receive technical handover and operational guidance. This ensures proper usage and helps minimize potential incidents during system operation—especially before the warranty and maintenance phase—thus preventing unexpected issues.

Why should you choose Fancons?

-

The leadership team has many years of experience in the field of industrial engineering.

-

Our experts, engineers, and architects are highly qualified and have worked for years in factories specializing in design, operation, and maintenance.

-

We maintain a highly professional working style, satisfying even international clients with the strictest standards.

-

We are a strategic partner of major industrial equipment suppliers in the field of industrial electricity.

-

We are committed to ensuring complete confidentiality of all customer information.

-

We have extensive experience working with large domestic and international clients.

![]() CONTACT NOW:

CONTACT NOW:

FANCONS CONSTRUCTION GENERAL CONTRACTOR JOINT STOCK COMPANY

Headquaters: Nam Cuong Building, La Khe Ward, Ha Noi City

Hotline: 09345 01 333

Email: cgc@fancons.com.vn

Website: https://fancons.com.vn/

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)