The construction of a factory foundation is a critical structural component that supports the entire load of the building. To ensure a high-quality, safe, and long-lasting factory project, the most essential factor is a solid and stable foundation. Below are some insights and experiences in factory foundation construction that Fancons would like to share.

Nội dung

Understanding factory foundation construction

Each factory project serves a different purpose depending on the needs of the business. Whether the factory is used for production, storage, or commercial space, its foundation directly impacts the safety of both people inside and outside the building.

Moreover, the stability of the structure significantly affects the safety of machinery, equipment, and company assets. Therefore, construction quality is always a top concern for every business.

The foundation of a factory plays a crucial role in supporting the entire structural load of the building.

The quality of the construction is determined by both the foundation design drawings and the actual structural integrity of the foundation system. The foundation is located beneath the base level of the factory and serves to anchor the building’s load into the ground, ensuring it can withstand the pressure of the entire structure.

Factory foundation structure

A typical factory foundation structure consists of three main components:

Footing slab (also known as the footing mat or foundation pad):

The footing slab helps interconnect the columns, forming a unified block in accordance with the factory foundation design standards. Its primary function is to evenly distribute loads across the structure, enhancing its overall stability.

Tie beams (also known as foundation beams or grade beams):

These components connect individual footings together to reinforce the foundation system. Tie beams help improve the rigidity of the foundation and, under heavy loads, help spread the force across a wider area to prevent structural deformation.

Foundation neck (also called foundation pedestal):

This is the uppermost part of the foundation and acts as the transition element that transfers loads from the superstructure down to the base. The height of the foundation neck must be carefully calculated and designed to match the overall foundation structure for optimal performance.

Popular types of factory foundation construction

Depending on the terrain and soil conditions of each area, different foundation construction methods are applied. Below are four common types of factory foundations that businesses can refer to:

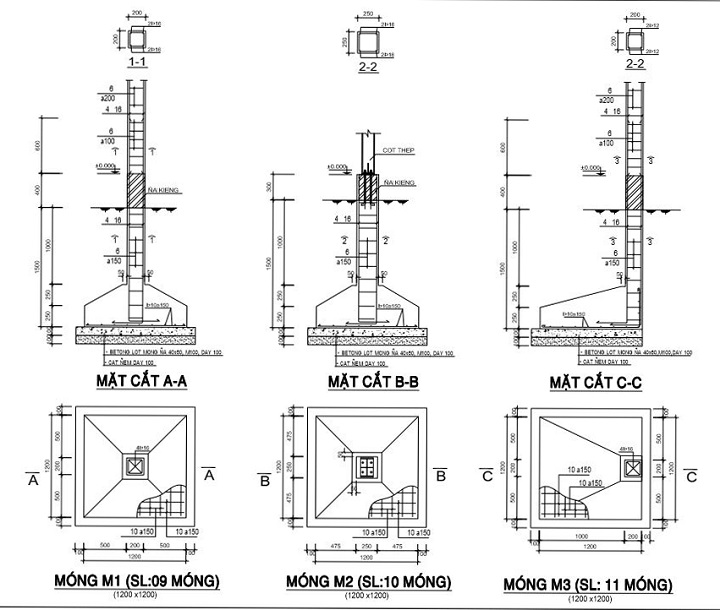

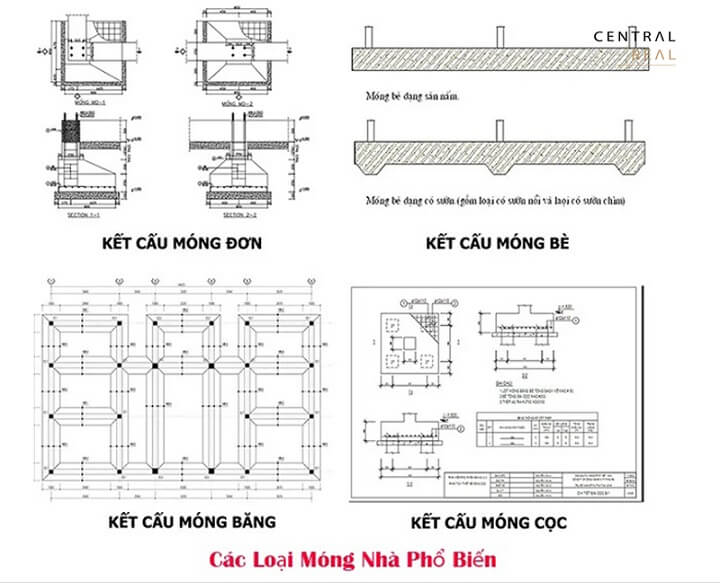

- Isolated Footing

Divided into four main types: independent footing, pillar footing, column footing, and pier footing.

This type is typically used for buildings with light loads such as residential houses, small factories, or warehouses.

Isolated footings are best suited for hard soil with good bearing capacity and where external loads are not too large. - Strip Footing

This is the most commonly used foundation type today.

Strip footings usually have the shape of long, narrow strips, either laid independently or connected in a grid (like a cross).

There are two basic types: One-way strip footing and two-way strip footing. These can be further categorized into rigid footings, flexible footings, or combined systems depending on structural requirements.

- Pile Foundation:

This type of foundation is mainly used in areas with weak soil and has a cylindrical shape. Materials such as concrete piles are driven deep into the ground to support and bear the load of the entire superstructure. There are two common types of pile foundations: low-cap pile foundations and high-cap pile foundations. - Raft Foundation:

Also known as a mat foundation, it is a shallow foundation that spreads over the entire ground area of the construction project. There are four types of raft foundations: flat raft, mushroom raft, ribbed raft, and box-type raft.

Essential factors for the factory foundation construction process

Before designing and constructing the factory foundation, the following points must be carefully considered:

-

Geological Survey:

Enterprises need to conduct a thorough geological survey of the intended construction site. -

Choosing the Foundation Type:

Based on the geological survey results, the construction unit will decide which type of foundation is most suitable. -

Construction Quality:

Skilled workers must carry out construction using proper techniques to ensure the safety and integrity of the project. -

Materials Used:

Using high-quality construction materials helps ensure the foundation’s functions are effectively fulfilled. -

Construction Contractor:

Enterprises should select reputable contractors with experienced, skilled workers to avoid potential problems during construction.

Factory Foundation Construction Process

The standard construction process for factory foundations includes the following steps:

Excavation of the Foundation Pit:

This stage makes good use of excavators and earth-moving trucks, reducing manual labor and saving time and costs for the enterprise. After excavation, the foundation pit surface should be leveled, usually by pouring a layer of concrete blinding. Note: Always keep the foundation pit dry.

Reinforcement Processing:

To speed up the construction progress, steel reinforcement shaping for the foundation base and column reinforcement can be done simultaneously with excavation.

Formwork Assembly:

Before pouring concrete for the foundation, plywood formwork is used to shape and contain the concrete. Common formwork sizes include 20cm x 4m, 25cm x 4m, and 30cm x 4m.

Concrete Pouring:

Workers must pay attention to the correct ratio of aggregate, sand, cement, and water to create a good concrete mix. Using a concrete mixer is recommended to save labor and shorten construction time.

Formwork Removal for Foundations

After confirming that the concrete has fully hardened, proceed to dismantle the formwork panels.

Curing After Foundation Construction

To achieve the best concrete strength and prevent cracking, it is essential to continuously keep the concrete moist throughout the curing period. Some common methods for curing concrete include: spraying water on the surface, covering with boards to minimize evaporation, or applying curing compounds.

Important Notes to Avoid During Foundation Construction

Inadequate Geological Survey

During the geological survey for foundation construction, avoid areas with excessively high-water tables which can cause dampness and damage the foundation. Additionally, ensure a safe distance between the groundwater level and the foundation—typically a minimum of 0.5 meters.

Improper Foundation Design

When designing foundation drawings, carefully study and apply appropriate methods to avoid the need for design changes during the construction phase.

Poor Quality Construction

This is a critical requirement, so businesses must choose reputable and experienced contractors. Poor quality foundation work can lead to problems such as cracking, settling, and floor leakage.

Neglecting Supervision During Foundation Construction

The foundation construction accounts for up to 40% of the total project value. Therefore, negligence in supervision can lead to unforeseeable consequences. Contractors must always carefully and closely monitor and urge the construction process.

Choosing Substandard Materials

It is essential to select high-quality materials that meet standards and have reasonable prices. Especially important is to choose reputable suppliers and thoroughly inspect materials upon delivery.

Conclusion

Above are some experiences in the process of foundation construction for industrial buildings that Fancons has gathered from various projects. We hope this information will supplement your knowledge and be useful during construction. If you need support or want to contribute ideas, please contact the Fancons architectural team via hotline: 09345 01 333.

FANCONS – SPECIALIZING IN DESIGN AND CONSTRUCTION OF INDUSTRIAL FACTORIES

Headquarters: Nam Cuong Building, La Khe Ward, Hanoi City.

Hotline: 09345 01 333.

Email: cgc@fancons.com.vn

Website: https://fancons.com.vn/

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)