Pre-engineered steel frame factory construction is a popular choice for businesses to save costs and construction time. The construction cost of pre-engineered steel frame factories can save businesses from 20% to 40% compared to conventional reinforced concrete factories. Let’s explore the details of pre-engineered steel frame factories with Fancons in the article below.

Nội dung

What is a Steel Frame Factory?

A pre-engineered steel frame factory (or pre-engineered factory) is a type of factory building constructed with a steel frame made of shaped steel sections or composite steel, assembled according to detailed technical design drawings.

All steel structures of the factory such as columns, trusses, purlins, etc., are prefabricated at steel structure factories based on the approved designs. Therefore, the on-site construction and assembly of the factory proceed very quickly.

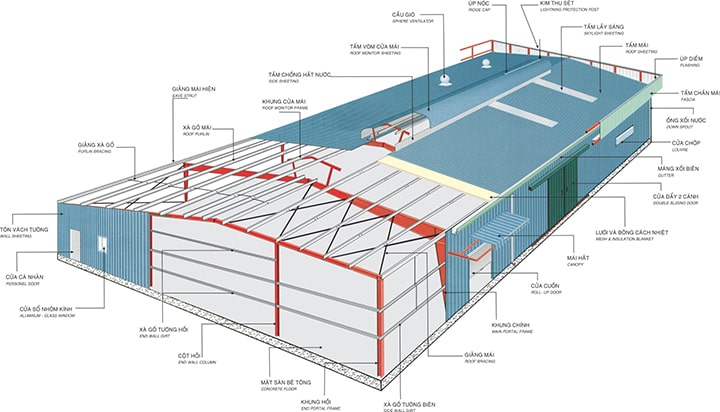

Structure of a Pre-engineered Steel Frame Factory

The pre-engineered steel factory includes four main components:

-

Main frame system (columns, trusses, beams)

-

Secondary structures (wall beams, purlins, braces, bracing system, etc.)

-

Roof sheeting and wall cladding sheets

-

Factory foundation system

Basic Parameters of Pre-Engineered Factories

These parameters help determine the design, technical requirements, and construction unit prices in contracts signed between investors and contractors.

-

Factory width: The width depends on the investor’s requirements. There is no limit to the factory’s width. The width is measured from the outer edge of one side of the building to the outer edge of the opposite side.

-

Factory length: The length depends on the requirements. There is no limit to the factory’s length. The length is measured from the outer edge of one end of the building to the outer edge of the opposite end.

-

Factory height: The height depends on requirements. It is measured from the floor level to the eave (the junction between the roof sheeting and wall cladding).

-

Roof slope: The roof slope affects rainwater drainage efficiency. Typically, the roof slope is 15%.

-

Column spacing: This is the distance between columns along the length of the factory. Column spacing is determined based on the building length and intended use of the factory.

-

Load: The calculated loads acting on the structure include: self-weight, roof live loads, wind load, crane runway loads, and operational loads.

Price quotation for pre-engineered steel factory construction

Note: Construction unit prices are for reference only and may change depending on the time and global steel prices. Investors who need consultation or erection of pre-engineered steel factories, please contact Fancons for the most accurate and prompt consultation and quotation.

Cost estimate for pre-engineered factory construction by each category

Steel Structure Fabrication Items

| Item | Unit | Unit Price (VND) |

|---|---|---|

| Steel trusses, beams spanning multiple bays | kg | 5,000 – 8,000 VND/kg |

| Steel plate raw materials provided by customer or at current steel market price | kg | According to market price (16,000 – 18,000 VND/kg) |

| Item | Unit | Unit Price (VND) |

| Erecting main truss frame | m² | 250,000 VND/m² |

| Erecting roof ridge frame | m² | 250,000 VND/m² |

| Erecting door cantilever (consonle) | m² | 250,000 VND/m² |

| Installing roof sheets (excluding insulation) | m² | 220,000 VND/m² |

| Installing wall sheets | m² | 225,000 VND/m² |

| Installing gutters and downpipes | m² | 275,000 VND/m² |

| Installing edge trims and flashings (ridge caps, eave trims, base trims, etc.) | m² | 25,000 VND/m² |

Process for Pricing Steel Frame Factory Building Structures

Fancons Construction Joint Stock Company always aims to deliver high-quality projects with optimal construction costs for investors. Fancons follows a transparent pricing process with solutions tailored to each company’s needs as follows:

- Consultation & Preliminary Design Provision: Fancons will thoroughly understand the company’s requirements to develop a preliminary design and propose suitable solutions, materials, along with a construction cost estimate for the factory building.

- Contract Signing: After the investor reviews and accepts the proposal, Fancons will finalize the contract and complete necessary legal procedures.

- After Contract Signing: Fancons will provide detailed technical designs that guide production, fabrication, and erection.

Steel Frame Factory Construction Process

The construction process for a steel frame factory includes seven main stages:

- Concept Development: Based on the investor’s initial ideas and requirements, Fancons proposes a detailed plan covering design, fabrication, erection, construction pricing, and timeline.

- Solution Proposal: Once the client agrees, Fancons presents optimal solutions regarding materials usage, cost estimation for steel factory construction, and project schedule.

- Contract Signing and Project Deployment: Upon investor’s approval, both parties sign the contract and commence project implementation.

- Technical Design Development: Leveraging the expertise of our team and modern design and material management software, Fancons commits to delivering a factory structure design that satisfies the client.

- Fabrication: A rigorous fabrication process using advanced equipment including 7 steps: steel cutting with CNC, plasma, automatic welding; surface cleaning; metal spraying; protective painting; galvanizing and alloy coating for purlins and roofing sheets; transportation to the site. 100% of products are inspected at the factory before delivery.

- Construction and Erection: All materials are packaged and transported to the site for construction. Every stage is strictly supervised to ensure the highest quality.

- Warranty: Fancons provides a 2-year warranty on materials, 3 years against leakage, and 10 years warranty on structural framework to optimize durability and performance.

The above are the updated 2022-unit prices for constructing pre-engineered steel frame factory buildings. If customers need consultation or detailed construction cost estimates for factory buildings or pre-engineered structures, please contact Fancons via email at cgc@fancons.com.vn or call our hotline at 09345 01 333 for direct assistance.

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)