Industrial garment factories are typically held to very high standards in both technical specifications and aesthetics, with the goal of maximizing business efficiency for the investor. So, what should be considered when designing an industrial garment factory? Fancons will share detailed insights in the article below.

Nội dung

Requirements in Industrial Garment Factory Design

An industrial garment factory is a specialized type of building, yet it still follows the principles of architectural design. At a minimum, an industrial garment factory design must meet the following three core requirements:

A functional layout with logical zoning

This is a critical factor in meeting the long-term operational needs of the investor. A well-planned and logically arranged functional layout will ensure smooth production processes and help achieve maximum labor productivity.

Optimizing Technical Solutions

The factory design must ensure structural safety. Garment factories also need to meet technical and construction requirements, which should be considered from the design phase.

Therefore, the selection of quality and safe building materials that suit the needs of the factory must be carefully calculated.

Creating an aesthetic and functional architectural work

Depending on the specific characteristics and requirements of the investor, garment factory designs may vary. However, they must still ensure a functional workspace, with equipment arranged in a logical, harmonious manner for ease of management.

Standards for designing and constructing industrial garment factories

The design and construction of an industrial garment factory must comply with the following standards:

International Design Standards:

-

AWS D1.1/D1.1M:2006: An American National Standard (American National Standards Institute)

-

AISC 360:2005: Specification for Structural Steel Buildings

-

MBMA 2002: Metal Building Systems Manual

-

ISO 9001:2015: Quality Management System Standard

Vietnamese Design Standards:

-

TCXD VN 338:2005: Steel Structures – Design Standards

-

TCVN 3223:1994: Welding Rods for Carbon Steel and Low Alloy Steel

-

TCVN 1916:1995: Bolts, Screws, Studs, and Nuts – Technical Requirements

Testing and Inspection:

-

TPI: Third Party Inspection

-

NDT: Non-Destructive Testing

-

MPI: Magnetic Particle Inspection

Industrial garment factory design process at Fancons

Just like other construction projects, the design and construction of industrial factories at Fancons follow these steps:

Step 1: Gathering Information from the Business

We receive requests from businesses and conduct on-site surveys of the construction area. To provide the most accurate consultation, Fancons’ expert team will directly measure and record the technical specifications of the site, thereby proposing the most suitable factory design solution.

Step 3: Preliminary Design Drawing

Fancons’ architects will create the preliminary design drawing based on the collected data and customer requirements. This drawing outlines the basic layout, structure, and spatial planning of the garment factory, forming the foundation for the next design stages.

If both parties reach a successful agreement, Fancons’ architects will prepare the technical drawings to present to the client.

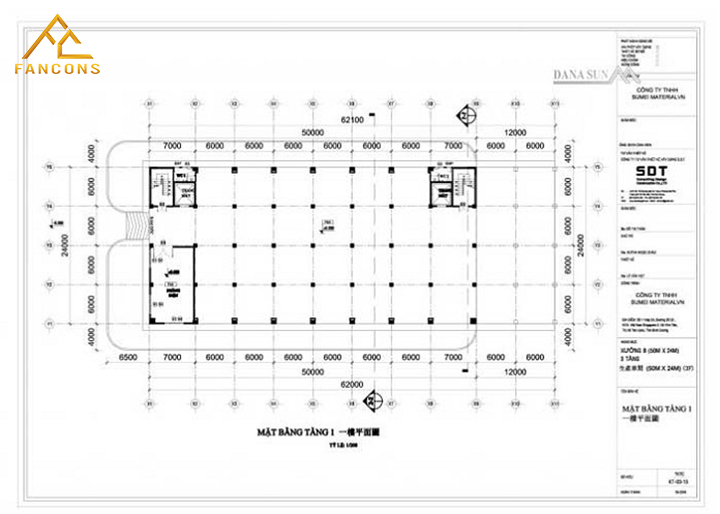

Step 3: Design drawings and 3D garment factory layout

If the investor approves the technical drawings and signs the contract, the architects will proceed to design a 3D perspective layout. This allows the investor to have a visual overview and make reasonable adjustments if needed.

Step 4: Receive feedback, make revisions, and finalize the design

After receiving feedback from the client, Fancons’ architects will proceed to revise and complete the design drawings according to the client’s requirements.

Important considerations when designing an industrial garment factory

Site considerations for the garment factory

When constructing an industrial garment factory, it is crucial to pay attention to the foundation and flooring, as they directly impact the quality of the building and the construction costs.

If the factory is located on hard ground with a high elevation compared to the construction level, foundation reinforcement methods such as piling or wooden stake driving may not be necessary.

On the other hand, if the foundation is built on soft or swampy ground, reinforcing the foundation becomes critical for the stability of the factory.

Cost considerations for designing an industrial garment factory

Optimizing the use of space is essential, especially as land rental costs continue to rise. Every square meter must be carefully calculated to maximize efficiency. Some businesses even build 2-story, 3-story, or even 5 to 7-story factories to use land more effectively.

Knowing the investment costs in advance, including contingency funds for unexpected expenses, helps in managing finances proactively. This is especially important when bank loans are required. A detailed calculation of costs and product pricing should be carried out right from the project planning stage.

Once you have a complete set of design documents, the owner (investor) can easily select a contractor and manage the construction in an organized, planned manner. This helps avoid extra costs and delays that arise when design and construction happen simultaneously.

Other important considerations

-

Keep all design documents and construction permits on file throughout the operation of the business. They serve essential purposes during factory maintenance, repairs, or future upgrades.

-

Apply effective, modern solutions throughout—from construction methods to technical systems such as advanced building materials, HVAC and ventilation systems, and robust lightning protection.

-

For expert advice on industrial garment factory planning. Please contact our hotline for detailed consultancy: 0934 5 01 333

FANCONS Construction General Co., Ltd.

Headoffice: Nam Cuong Buiding, La Khe Ward, Ha Noi City

Hotline: 09345 01 333

Email: cgc@fancons.com.vn

Website: https://fancons.com.vn/

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)